Reverse

Engineering

Breathing New Life into Existing Products

At Oxta Design Australia, our reverse engineering services are designed to help Australian businesses uncover, analyse, and enhance the functionality of existing products or legacy components. Whether you’re looking to recreate a discontinued part, digitise an old mechanical assembly, or improve an existing design for modern use — we bring deep technical expertise and local market understanding to every project.

From our base in Sydney, we work with clients across Melbourne, Brisbane, Adelaide, Perth, and regional areas to provide detailed CAD models, technical documentation, and manufacturing-ready data derived from physical products.

What is Reverse Engineering?

Reverse engineering is the process of deconstructing a physical product to understand its design, functionality, and material composition. It enables engineers to reproduce or improve existing components, often when original drawings or manufacturer data are unavailable. Through 3D scanning, manual measurement, and CAD reconstruction, we create digital twins of legacy products or tools.

At Oxta Design, we apply reverse engineering not only to replicate — but to refine, optimise, and future-proof your product.

Why Reverse Engineering is Essential in Australia

Australia’s diverse industrial landscape — from mining in Perth to agriculture in rural Victoria — relies heavily on machinery, infrastructure, and products that often outlive their original documentation or manufacturers. In such cases, reverse engineering becomes critical.

Here’s how reverse engineering benefits Australian businesses:

Replace Obsolete Parts: Recreate discontinued or hard-to-source components.

Improve Performance: Analyse weaknesses or inefficiencies and redesign for durability.

Update for Compliance: Ensure old designs meet modern Australian standards (AS/NZS).

Cost-Effective Production: Redesign for manufacturability using local suppliers and technologies.

Digitisation: Create accurate CAD models for archiving, simulation, or training purposes.

Whether you’re in Sydney looking to modernise an appliance, or a manufacturer in Adelaide seeking to localise part production, reverse engineering is the bridge between legacy and innovation.

Our Reverse Engineering Services

We offer a flexible, client-focused process that can be tailored to suit small components, large machinery, or entire assemblies. Our engineers and designers work hands-on with physical samples, using a blend of manual and digital techniques.

1. Part Assessment & Project Scoping

We begin by reviewing your part or product to understand its purpose, tolerances, materials, and operating environment. This includes wear analysis, stress points, and fitment requirements.

2. Measurement & 3D Scanning

We capture geometric data using:

High-precision calipers and gauges

Structured light or laser 3D scanning

Photogrammetry (for large or complex shapes)

3. CAD Reconstruction

Using SolidWorks, Fusion 360, or Siemens NX, we rebuild the part as a fully parametric 3D model. Where necessary, we include:

Functional adjustments

Manufacturing enhancements

Material substitutions for cost or performance gains

4. Technical Documentation

We produce a full suite of technical deliverables:

2D engineering drawings

Tolerance callouts

Assembly instructions

Material and finish specifications

Exploded views and BOMs

5. Redesign & Optimisation (Optional)

If your goal is not just to replicate, but to improve, we offer:

Structural improvements

Lightweighting

Consolidation of multiple parts into one

Design for injection moulding or CNC machining

Cost optimisation based on Australian manufacturing methods

6. Prototyping & Manufacturing Support

Once your new design is validated, we assist with producing functional prototypes using 3D printing, machining, or casting. We also connect you with trusted Australian manufacturers for production runs.

Common Use Cases in Australia

Reverse engineering is not just for aged machinery. It’s widely used across industries:

Mining & Resources: Replacing worn components and improving durability

Agriculture: Adapting imported machinery for local conditions

Consumer Goods: Improving ergonomics or aesthetics of existing designs

Medical Devices: Updating legacy equipment to meet modern compliance

Manufacturing: Replicating moulds, dies, or jigs with better material handling

Automotive & Motorsport: Recreating rare or custom parts for older models

Heritage Restoration: Digitising and preserving historical artefacts or tools

Working with Oxta Design

1. Precision and Attention to Detail

Our engineering team treats every component with the care it deserves — capturing the exact dimensions and relationships needed for a faithful, high-quality replication.

2. Australian Industry Knowledge

We understand the materials, tolerances, and finishes commonly used across Australian sectors — and we design accordingly.

3. Digital Documentation for the Future

Beyond replication, we help you build a digital library of technical assets, making it easier to maintain, share, or update designs long into the future.

4. Local Support

Need someone to visit your site in Sydney? Or ship a part from Brisbane? Our network spans across Australia, ensuring seamless communication and fast turnaround.

Tools & Software We Use

SolidWorks & Fusion 360 for 3D CAD

Alibre & Siemens NX for precision parts

Geomagic & MeshLab for scan cleanup and point cloud processing

KeyShot & Blender for visualisation

3D scanning equipment: EinScan, Artec Eva, Revopoint

We also maintain compatibility with STEP, IGES, STL, DXF, and native files for most CNC and CAM software.

Sydney-Based, Nationwide Reach

Though we’re headquartered in Sydney, our reverse engineering services are trusted by clients in:

Melbourne – Manufacturing, tooling, and automotive

Brisbane – Agri-tech, irrigation systems, and rural machinery

Perth – Mining, oil & gas, and heavy industrial machinery

Adelaide – Aerospace, defence components, and electronics housings

Canberra – R&D labs and restoration projects

We serve both urban and regional clients, adapting our process to meet your specific needs and technical complexity.

Why Us ?

At Oxta Design Australia, we don’t just design products — we engineer bold, meaningful solutions through a structured, collaborative approach. Our phased process transforms your initial idea into a refined, market-ready innovation designed to thrive in the Australian and global markets.

01. Collaborate

True innovation begins with collaboration. At Oxta Design Australia, we believe strong partnerships are built on trust, openness, and shared vision. We integrate with your team from the outset through dynamic workshops and ongoing discussions to unpack your goals and pinpoint areas where design can truly make a difference.

02. Immerse

We dig deep into user needs, industry context, and behavioural insights through multi-dimensional research. Whether it's ethnographic observation, stakeholder interviews, or macro trend analysis, we gather the insights needed to design for people — not just products.

03. Create

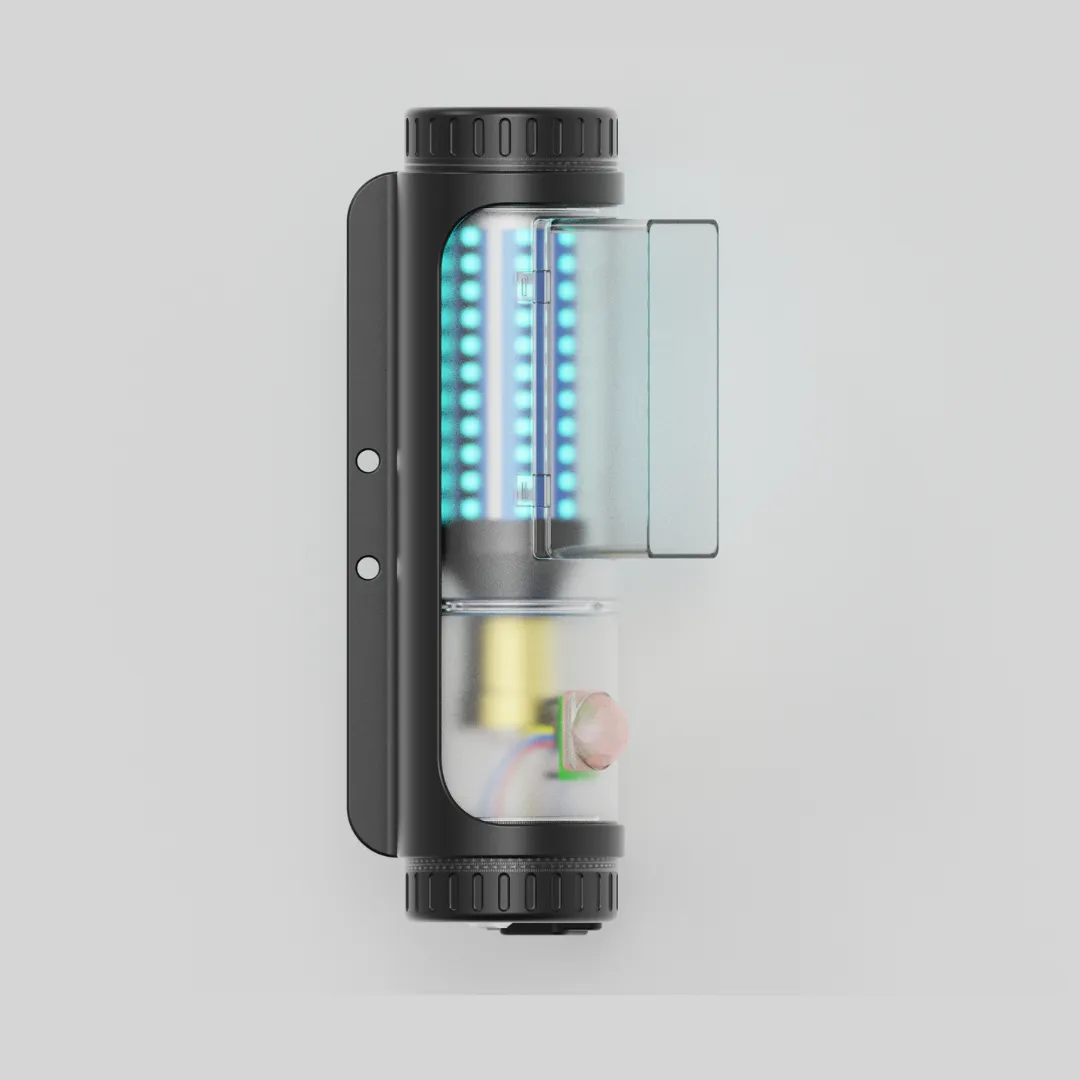

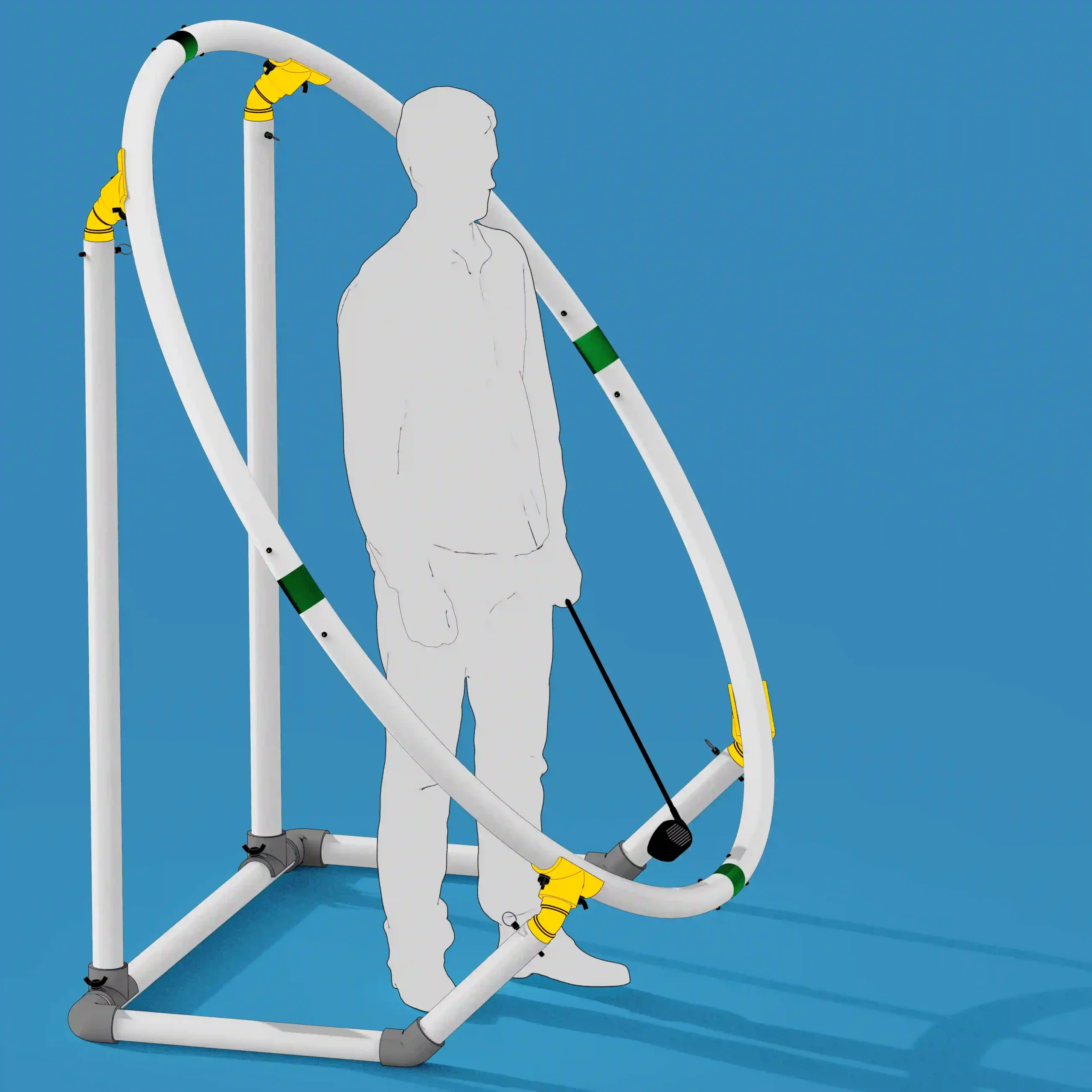

With insights in hand, we move into concept development. Here we translate strategy into form — exploring multiple design directions and narratives that reflect your brand values and resonate with your audience. Visual storytelling through expressive sketches, CAD mockups, and early models ensures every idea is grounded in feasibility and inspiration.

04. Refine

We take promising concepts and evolve them into robust, engineered solutions. Our industrial designers and mechanical engineers collaborate to iterate, prototype, and test every detail. From CAD development to full CMF (colour, material, finish) refinement and physical rig testing — nothing is left to chance.

05. Deliver

When your product is ready for launch, we make sure it's ready for real-world production. We work with trusted Australian and global manufacturers to bring your product to life at scale — managing everything from tooling and compliance to visual assets for investors, trade shows, and product launch campaigns.

Support

Our partnership doesn't end at delivery. We continue to provide post-launch support, technical guidance, and iteration assistance based on market feedback. Whether it’s scaling production, updating designs, or assisting with marketing materials — we’re here to back your success long-term.

Portfolio

Take a look at our portfolio to see how we’ve helped businesses across various industries transform their digital presence. Each project is a testament to our commitment to creativity, quality, and innovation.

FAQ

Frequently Asked Questions

Stay up-to-date with the latest trends in design, technology, and digital media. Our news section features insights,

updates, and stories from our team, showcasing our ongoing projects and industry innovations.

Our pricing is transparent and structured. We provide detailed estimates before initiating each project stage, with costs outlined for your clarity. A 50% deposit is required to commence work, with the balance due upon stage completion. We eschew hourly fees, focusing instead on delivering value.