Rapid Prototyping

Rapid

Prototyping

Accelerate your product development with high-quality prototypes that validate design, functionality, and fit — delivered with speed and local expertise.

From CAD to Reality — Fast, Accurate, and Built for Australia

At Oxta Design Australia, we help businesses bring ideas to life through precision-engineered, fast-turnaround prototyping. Whether you need a quick form model, a functional mechanical assembly, or a fully finished unit ready for user testing, our rapid prototyping services are designed for today’s pace of innovation.

From Sydney’s innovation hubs to Melbourne’s product studios, from Brisbane’s industrial workshops to Perth’s mining R&D departments — Australian creators trust us to turn CAD into something you can hold, test, and refine.

Our team combines industrial design, mechanical engineering, and real-world manufacturing insight to create prototypes that are as informative as they are impressive.

Why Rapid Prototyping is Essential in the Australian Market

Australia’s innovation scene is booming — but local businesses face time, cost, and distance challenges. Rapid prototyping allows you to:

Test Ideas Quickly – Physically validate size, fit, ergonomics, and usability

Refine Before Tooling – Fix design flaws before committing to expensive production

Communicate Visually – Impress stakeholders, investors, and early customers with a tangible prototype

Speed Up Decision Making – Iterate faster and smarter during development

Shorten Time-to-Market – Build momentum and keep your product roadmap on track

Whether you’re an early-stage startup in Sydney or an OEM in Adelaide refining a new tool, prototyping helps reduce risk while increasing confidence.

What We Offer

We offer a range of rapid prototyping services, tailored to your product stage, purpose, and budget:

1. Form & Fit Models

Ideal for assessing:

Product proportions and ergonomics

Packaging compatibility

Internal layout and component clearance

User interface mockups

Materials: PLA, ABS, PU foam, MDF, acrylics

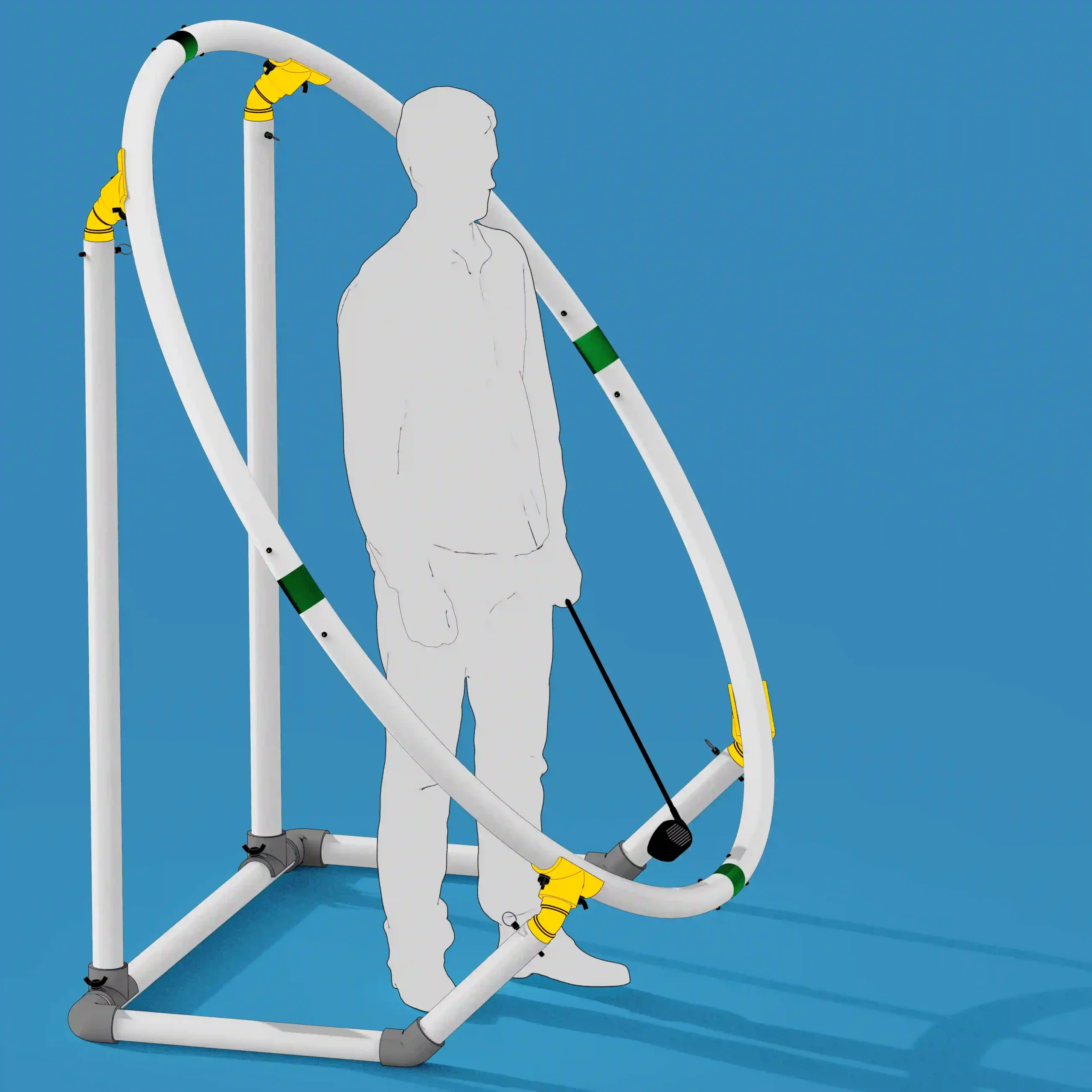

2. Functional Prototypes

Designed to test:

Mechanisms and moving parts

Load bearing or structural behaviour

Electrical/electronic integration

Snap fits, hinges, locks, threads

Technologies: SLS, FDM, SLA, CNC machining, silicone casting

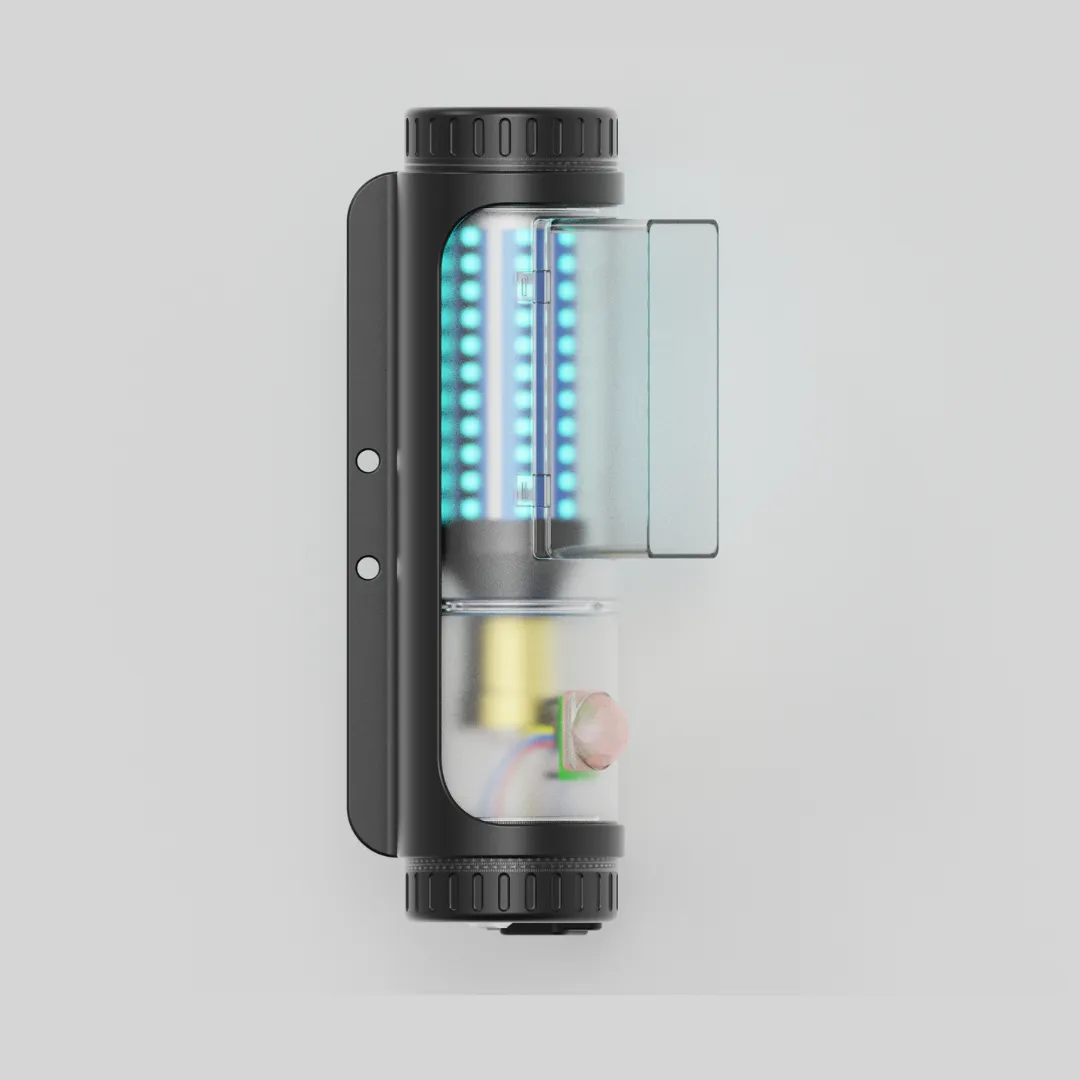

3. High-Fidelity Appearance Prototypes

Used for:

Trade shows or investor presentations

Marketing & photoshoots

Industrial design validation

Consumer feedback and surveys

Finishes: Painted, textured, soft-touch, chromed, transparent, rubberised.

4. Assembly & Test Units

Multi-part builds that:

Simulate final product feel and function

Include electronics, sensors, and displays

Validate assembly and disassembly processes

We also include detailed documentation to support design changes and production transition.

Materials & Methods We Use

Additive Manufacturing:

FDM (Fused Deposition Modelling): Cost-effective for form models

SLA (Stereolithography): Smooth finishes and fine details

SLS (Selective Laser Sintering): Strong, functional parts

MJF (Multi Jet Fusion): High-detail nylon-based prototypes

Subtractive Manufacturing:

CNC Machining (Plastics, Aluminium, Brass)

Laser Cutting (Acrylics, MDF, Steel)

Other Techniques:

Polyurethane vacuum casting

Silicone molding

Hand finishing and painting

We match your prototype to its intended purpose — form, function, or appearance — ensuring the right material, process, and timeline.

Industries We Serve

We help clients across multiple industries in Australia:

Consumer Electronics – Enclosures, wearables, and smart devices

Furniture & Homewares – Design validation for timber, plastic, and metal builds

Automotive & Motorsport – Custom brackets, housings, intake parts

Healthcare – Medical device mockups, ergonomic tools

Mining & Industrial – Rugged housings, handles, protective enclosures

Agriculture – Irrigation tools, harvesting aids, sensor housings

Our clients include product startups, government-funded research groups, manufacturers, and established brands.

Our Process

We follow a clear and flexible prototyping workflow:

Design Review & Purpose Discussion – Understanding how the prototype will be used

Material & Method Selection – Based on functional needs and cost

Production Setup – Preparing files and toolpaths

Fabrication – Using the appropriate 3D printing, machining, or casting techniques

Post-Processing – Sanding, painting, polishing, or assembling parts

Delivery or Testing – Shipped to your door or tested in our Sydney facility

We also support multiple iterations and fast design adjustments for teams working in agile environments.

Where We Work

Our core studio is based in Sydney, and we work with clients across Melbourne, Brisbane, Perth, Adelaide, and regional Australia. Whether it’s a face-to-face workshop or a fully remote project, we’ve successfully collaborated with startups, SMEs, and enterprise clients across industries.

Why Us ?

At Oxta Design Australia, we don’t just design products — we engineer bold, meaningful solutions through a structured, collaborative approach. Our phased process transforms your initial idea into a refined, market-ready innovation designed to thrive in the Australian and global markets.

01. Collaborate

True innovation begins with collaboration. At Oxta Design Australia, we believe strong partnerships are built on trust, openness, and shared vision. We integrate with your team from the outset through dynamic workshops and ongoing discussions to unpack your goals and pinpoint areas where design can truly make a difference.

02. Immerse

We dig deep into user needs, industry context, and behavioural insights through multi-dimensional research. Whether it's ethnographic observation, stakeholder interviews, or macro trend analysis, we gather the insights needed to design for people — not just products.

03. Create

With insights in hand, we move into concept development. Here we translate strategy into form — exploring multiple design directions and narratives that reflect your brand values and resonate with your audience. Visual storytelling through expressive sketches, CAD mockups, and early models ensures every idea is grounded in feasibility and inspiration.

04. Refine

We take promising concepts and evolve them into robust, engineered solutions. Our industrial designers and mechanical engineers collaborate to iterate, prototype, and test every detail. From CAD development to full CMF (colour, material, finish) refinement and physical rig testing — nothing is left to chance.

05. Deliver

When your product is ready for launch, we make sure it's ready for real-world production. We work with trusted Australian and global manufacturers to bring your product to life at scale — managing everything from tooling and compliance to visual assets for investors, trade shows, and product launch campaigns.

Support

Our partnership doesn't end at delivery. We continue to provide post-launch support, technical guidance, and iteration assistance based on market feedback. Whether it’s scaling production, updating designs, or assisting with marketing materials — we’re here to back your success long-term.

Portfolio

Take a look at our portfolio to see how we’ve helped businesses across various industries transform their digital presence. Each project is a testament to our commitment to creativity, quality, and innovation.

FAQ

Frequently Asked Questions

Stay up-to-date with the latest trends in design, technology, and digital media. Our news section features insights,

updates, and stories from our team, showcasing our ongoing projects and industry innovations.

Our pricing is transparent and structured. We provide detailed estimates before initiating each project stage, with costs outlined for your clarity. A 50% deposit is required to commence work, with the balance due upon stage completion. We eschew hourly fees, focusing instead on delivering value.