Electronics

Design

Smart, Connected, and Built for the Real World

At Oxta Design Australia, we provide full-spectrum electronics design services that take your ideas from initial concept to production-ready hardware. Whether you’re developing a consumer gadget in Sydney, an IoT device in Melbourne, or an industrial sensor system in Brisbane, our experienced electronics engineers can help you bring intelligent, reliable, and scalable electronic solutions to life.

From embedded systems and PCB design to firmware development and prototyping, we deliver smart designs tailored for the Australian market — compliant, manufacturable, and built to last.

What Is Electronics Design?

Electronics design is the process of creating the hardware and firmware that power modern digital devices. It encompasses the selection of components, circuit design, PCB layout, embedded software development, signal integrity, and functional testing. Whether it’s a simple battery-powered board or a complex IoT-connected system, electronics design is at the core of smart product innovation.

At Oxta Design, we blend innovation with engineering rigour to develop electronic systems that are compact, power-efficient, user-friendly, and production-ready — designed to work reliably in Australia’s diverse environments.

Why Electronics Design Matters for Australian Companies

As Australian industries embrace smarter, data-driven technologies, the demand for custom electronics is rapidly growing. Whether you’re in consumer tech, agriculture, mining, medical, or automation — embedded electronics are critical for differentiation and performance.

When designed correctly, electronics can:

Enhance product functionality

Enable wireless connectivity, sensors, and control

Improve energy efficiency

Unlock data tracking and smart automation

Reduce production and maintenance costs

Meet Australian compliance standards (RCM, EMC, etc.)

Our End-to-End Electronics Design Services

Our Sydney-based team works with startups, manufacturers, and research groups across Australia to deliver electronics that perform under real-world conditions. We work from early-stage scoping right through to production handover.

1. Requirements Gathering & Feasibility Study

We begin with a technical discovery process, understanding what your product needs to do, where it will operate, and how users will interact with it. We assess feasibility, recommend architectures, and align the design with power, cost, and certification constraints.

2. Schematic Design & Component Selection

Using Altium Designer and other industry tools, we develop robust circuit schematics and select reliable components based on local availability and long-term sourcing. We consider power budgets, signal paths, and thermal profiles early in the process.

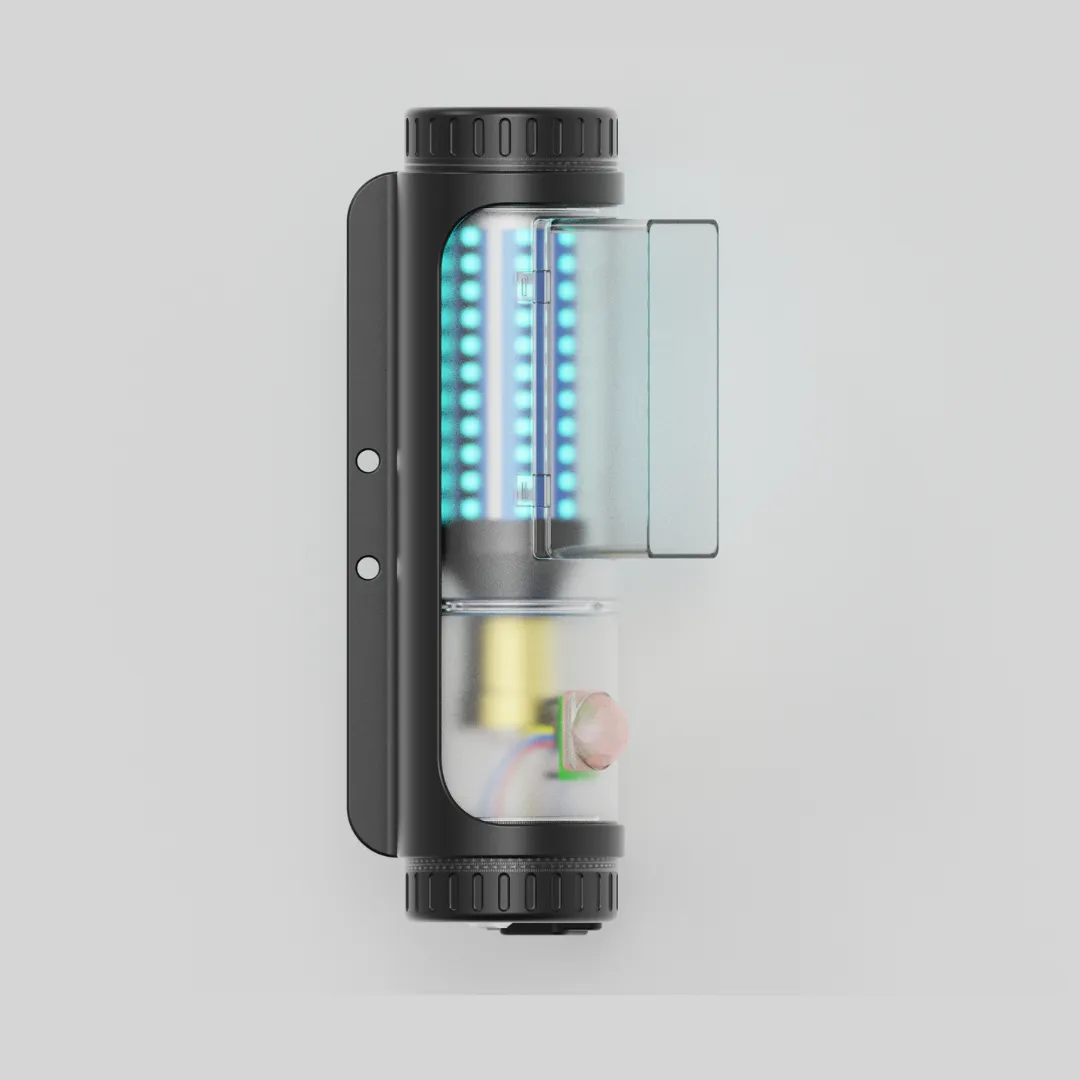

3. PCB Layout & Design for Manufacture

We design multi-layer PCBs with layout strategies optimised for manufacturability, EMI/EMC performance, and mechanical integration. Our designs are ready for fabrication at Australian PCB houses or offshore facilities — complete with gerbers, pick-and-place files, and test points.

4. Embedded Firmware Development

We develop low-level firmware for microcontrollers (ARM, AVR, ESP, STM32, etc.) and interface protocols like I2C, SPI, UART, BLE, Wi-Fi, and LoRa. Our firmware is lightweight, efficient, and tailored to your application — from sensor readings to power management and wireless updates.

5. Prototyping & Validation

We assemble and test fully functional electronic prototypes in collaboration with local partners. We run stress tests, power monitoring, signal analysis, and validation cycles to ensure real-world reliability.

6. Design for Certification

Electronics in Australia must meet EMC and radio compliance requirements. We design and test your product to prepare for RCM certification, AS/NZS standards, and other relevant compliance benchmarks. We also support pre-compliance testing and liaise with local test labs.

7. Production Handover

We provide full manufacturing files — including BOMs, gerber files, assembly drawings, test procedures, and firmware — for seamless transition to production. We assist with sourcing, cost reduction, and version control as your product scales.

Local Knowledge, Real-World Experience

Designing electronics for the Australian environment requires more than good schematics. Our team understands the practical challenges: dust in rural installations, heat stress in industrial zones, wireless interference in urban hubs, and power constraints in off-grid setups.

We’ve worked on:

Smart home and building automation

Consumer wearables and connected devices

Agricultural sensors and telemetry

Industrial control systems

Battery-powered and solar devices

Healthcare monitoring solutions

IoT-enabled tools for trades and mining

Our experience spans:

Home and lifestyle products

Electronics and smart devices

Medical and wellness equipment

Outdoor and sporting goods

Construction and trade tools

Kitchen and food-tech innovations

CAD and Simulation Support

In addition to circuit design, we ensure mechanical-electrical integration by working closely with our in-house CAD and industrial design teams. We offer:

3D component footprint mapping

Thermal analysis and enclosure airflow planning

Battery enclosure design

PCB stackup integration with mechanical constraints

EMI shielding and grounding strategy

Why Work with Oxta Design for Electronics?

1. Australian-Made Design, Global-Ready Standards

We design electronics locally, aligning with Australian compliance and manufacturing requirements while ensuring readiness for global expansion.

2. Embedded Innovation

We keep up with the latest in low-power design, wireless modules, cloud connectivity, and modular firmware architecture. Whether you’re building a one-off prototype or an IoT platform, we’ve got the technical edge.

3. Seamless Hardware-Software Integration

Our electronics design integrates smoothly with UI/UX, mobile apps, or cloud dashboards—creating a unified user experience.

4. Trusted by Startups and Manufacturers

From bootstrapped entrepreneurs to multi-national clients, we’ve delivered successful electronic products that now live on shelves, in homes, in fields, and in factories.

Cities We Serve

Though based in Sydney, we proudly serve innovators across:

Melbourne – Medical devices, automation, and consumer tech

Brisbane – Agri-tech, mining safety devices, and sensor systems

Adelaide – Clean tech, defence-grade electronics, and instrumentation

Perth – Mining IoT, rugged equipment, and remote sensing

Canberra & Hobart – Research tech, smart energy, and experimental devices

We work with both local assembly houses and large-scale overseas EMS providers to ensure your product is scalable and cost-effective.

Why Us ?

At Oxta Design Australia, we don’t just design products — we engineer bold, meaningful solutions through a structured, collaborative approach. Our phased process transforms your initial idea into a refined, market-ready innovation designed to thrive in the Australian and global markets.

01. Collaborate

True innovation begins with collaboration. At Oxta Design Australia, we believe strong partnerships are built on trust, openness, and shared vision. We integrate with your team from the outset through dynamic workshops and ongoing discussions to unpack your goals and pinpoint areas where design can truly make a difference.

02. Immerse

We dig deep into user needs, industry context, and behavioural insights through multi-dimensional research. Whether it's ethnographic observation, stakeholder interviews, or macro trend analysis, we gather the insights needed to design for people — not just products.

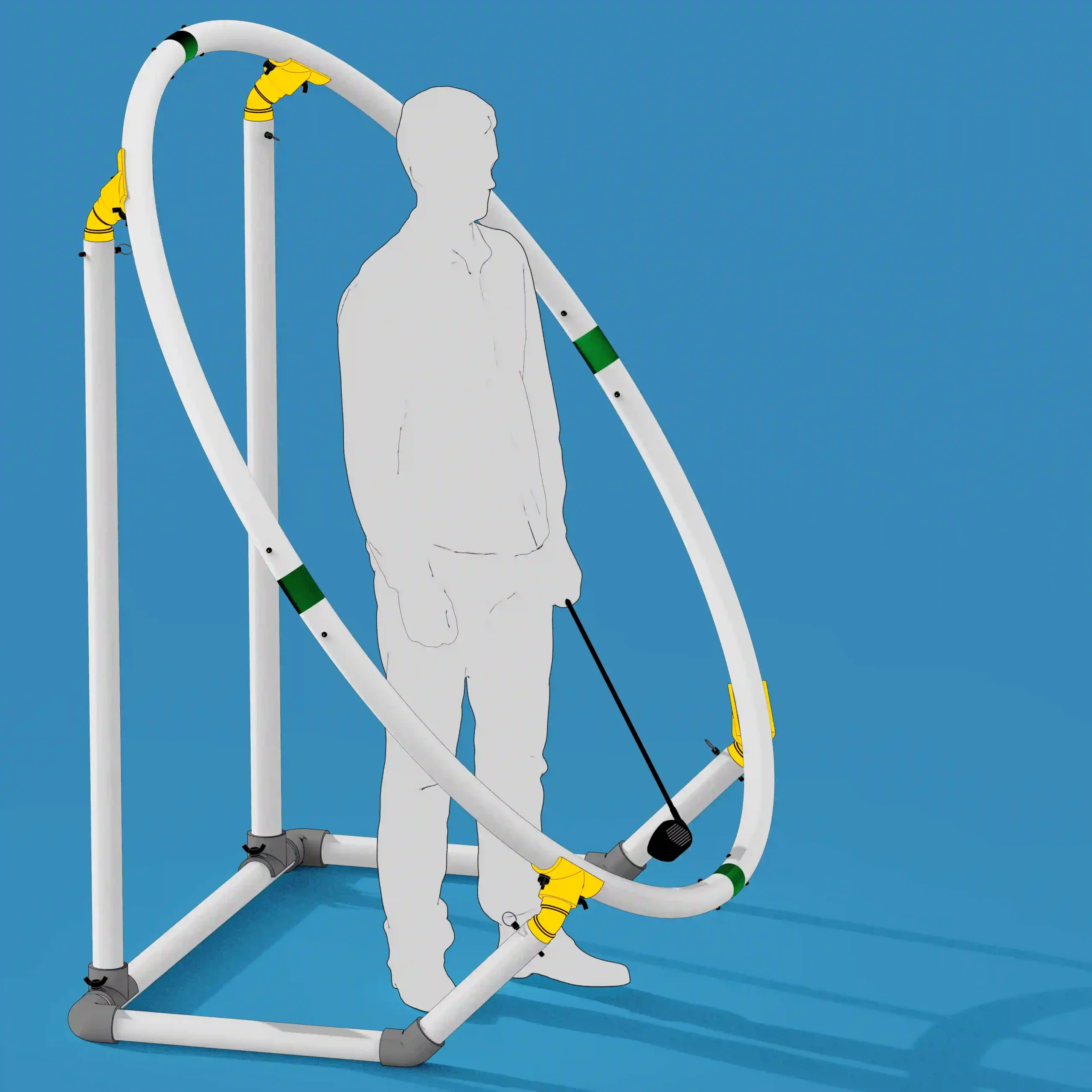

03. Create

With insights in hand, we move into concept development. Here we translate strategy into form — exploring multiple design directions and narratives that reflect your brand values and resonate with your audience. Visual storytelling through expressive sketches, CAD mockups, and early models ensures every idea is grounded in feasibility and inspiration.

04. Refine

We take promising concepts and evolve them into robust, engineered solutions. Our industrial designers and mechanical engineers collaborate to iterate, prototype, and test every detail. From CAD development to full CMF (colour, material, finish) refinement and physical rig testing — nothing is left to chance.

05. Deliver

When your product is ready for launch, we make sure it's ready for real-world production. We work with trusted Australian and global manufacturers to bring your product to life at scale — managing everything from tooling and compliance to visual assets for investors, trade shows, and product launch campaigns.

Support

Our partnership doesn't end at delivery. We continue to provide post-launch support, technical guidance, and iteration assistance based on market feedback. Whether it’s scaling production, updating designs, or assisting with marketing materials — we’re here to back your success long-term.

Portfolio

Take a look at our portfolio to see how we’ve helped businesses across various industries transform their digital presence. Each project is a testament to our commitment to creativity, quality, and innovation.

FAQ

Frequently Asked Questions

Stay up-to-date with the latest trends in design, technology, and digital media. Our news section features insights,

updates, and stories from our team, showcasing our ongoing projects and industry innovations.

Our pricing is transparent and structured. We provide detailed estimates before initiating each project stage, with costs outlined for your clarity. A 50% deposit is required to commence work, with the balance due upon stage completion. We eschew hourly fees, focusing instead on delivering value.