Design for

Manufacture (DFM)

We help Australian businesses transition from prototypes to scalable, cost-effective manufacturing — without compromising on quality or performance.

Seamless Design-to-Production Solutions for Australian Innovators

At Oxta Design Australia, we specialise in Design for Manufacture (DFM) services tailored to local production needs. Our goal is simple: to ensure your product not only looks and functions well but is also engineered for efficient, repeatable, and cost-effective production.

Headquartered in Sydney and serving manufacturers, startups, and inventors across Melbourne, Brisbane, Perth, Adelaide and beyond, our DFM process eliminates design flaws early, reduces manufacturing costs, shortens lead times, and ensures your product is ready for mass production — whether you’re making 100 or 100,000 units.

From injection molding and CNC machining to 3D printing, die casting, metal fabrication, and assembly — we design with real-world production in mind.

Why DFM is Critical in Australia

Australia presents a unique landscape for product manufacturing. Labour costs are higher, lead times must be optimised, and efficient production is key to staying competitive against imports.

Effective Design for Manufacture enables:

Cost Reduction – Minimise waste, machining time, and material costs

Fewer Production Delays – Prevent errors and tooling rework

Scalable Design – Plan ahead for production volumes and assembly processes

Better Quality Control – Build tolerances and specifications into the design

Simplified Assembly – Fewer parts, faster builds, and less reliance on skilled labor

By integrating DFM from the start, Sydney-based manufacturers and national enterprises alike can bring new products to market quicker and more competitively.

Our DFM Services

Our team of product engineers, industrial designers, and manufacturing specialists work hand-in-hand to develop designs that meet both aesthetic and engineering goals — while being production-ready.

1. Design Review & Optimisation

We assess your product at the concept, prototype, or pre-production stage to identify:

Undercuts and complex geometries

Tolerance issues

High-cost features

Assembly bottlenecks

Materials and finishing challenges

We then make recommendations for redesign to improve manufacturability without sacrificing function or design intent.

2. Material Selection & Sourcing Guidance

We help select the right material — balancing performance, cost, availability, and local sourcing. Whether you’re working with ABS, polypropylene, aluminium, stainless steel, or custom elastomers — we’ll match your design to what’s feasible in the Australian supply chain.

3. Process-Specific Design Adjustments

Every manufacturing method has its strengths and limitations. We design with your chosen process in mind:

Injection Moulding: Draft angles, wall thickness, gate placement

CNC Machining: Tool access, fillet radii, clamping design

Sheet Metal Fabrication: Bend radii, reliefs, tab & slot features

Die Casting: Shrinkage control, cooling flow, draft relief

Additive Manufacturing (3D Printing): Layer orientation, support minimisation, part consolidation

4. Tolerance Engineering & GD&T

We define tolerances that balance cost and functionality. We use AS1100 and ISO standards to ensure:

Functional fit

Repeatability

Interchangeability

Consistency across batches

5. Assembly Strategy & Part Consolidation

We reduce part counts where possible, enabling:

Easier, faster assembly

Reduced chances of errors

Lower tooling and labour costs

Seamless integration with automated or semi-automated processes

6. Prototype to Production Transition

Already have a working prototype? We’ll help you transition it into something that can be manufactured reliably:

Scalable part design

Optimised BOMs

Documentation for suppliers

Local or offshore production support

Our DFM Process

Discovery & Concept Review – Understand your product, goals and constraints

Manufacturing Method Selection – Based on part complexity, volumes, and cost targets

Design Refinement – Modify CAD, materials, and assembly as needed

Prototyping (Optional) – Validate new designs physically or with simulation

Supplier Handoff – Provide documentation for quoting, tooling and production

We work as an extension of your team — aligning with your in-house engineers, procurement team, or local manufacturers.

Tools We Use

CAD Software: SolidWorks, Fusion 360, Siemens NX

Simulation Tools: FEA and draft analysis for part strength and manufacturability

Rendering & Documentation: KeyShot, Adobe Illustrator, and drawing standards AS1100

We provide complete manufacturing drawings, BOMs, DXFs, and STEP/IGES files — all ready for immediate supplier handoff.

Why Oxta Design for DFM?

1. Australian Manufacturing Insight

We know the capabilities, limitations, and costs involved in producing locally — from high-precision CNC shops in Sydney to injection moulders in Melbourne.

2. Hands-On Prototyping Knowledge

Our in-house design team has built and tested hundreds of prototypes, and we apply that practical knowledge to refine every DFM project.

3. Cross-Disciplinary Engineering

We bring together designers, engineers, and supply chain advisors to deliver a holistic solution that fits your production needs.

4. Speed & Flexibility

We understand how to move fast without compromising accuracy — perfect for startups, pilot runs, and agile design teams.

Sydney-Based, Delivering Nationwide

Our team is based in Sydney, but we work with:

Melbourne – Furniture, industrial design, and tooling suppliers

Brisbane – Rural tech, agricultural machinery

Adelaide – Defence prototyping, metal fabrication

Perth – Mining sector components, rugged enclosures

Canberra – Tech hardware and enclosures for R&D labs

Wherever you are in Australia, we design with your manufacturing resources and regional capabilities in mind.

Why Us ?

At Oxta Design Australia, we don’t just design products — we engineer bold, meaningful solutions through a structured, collaborative approach. Our phased process transforms your initial idea into a refined, market-ready innovation designed to thrive in the Australian and global markets.

01. Collaborate

True innovation begins with collaboration. At Oxta Design Australia, we believe strong partnerships are built on trust, openness, and shared vision. We integrate with your team from the outset through dynamic workshops and ongoing discussions to unpack your goals and pinpoint areas where design can truly make a difference.

02. Immerse

We dig deep into user needs, industry context, and behavioural insights through multi-dimensional research. Whether it's ethnographic observation, stakeholder interviews, or macro trend analysis, we gather the insights needed to design for people — not just products.

03. Create

With insights in hand, we move into concept development. Here we translate strategy into form — exploring multiple design directions and narratives that reflect your brand values and resonate with your audience. Visual storytelling through expressive sketches, CAD mockups, and early models ensures every idea is grounded in feasibility and inspiration.

04. Refine

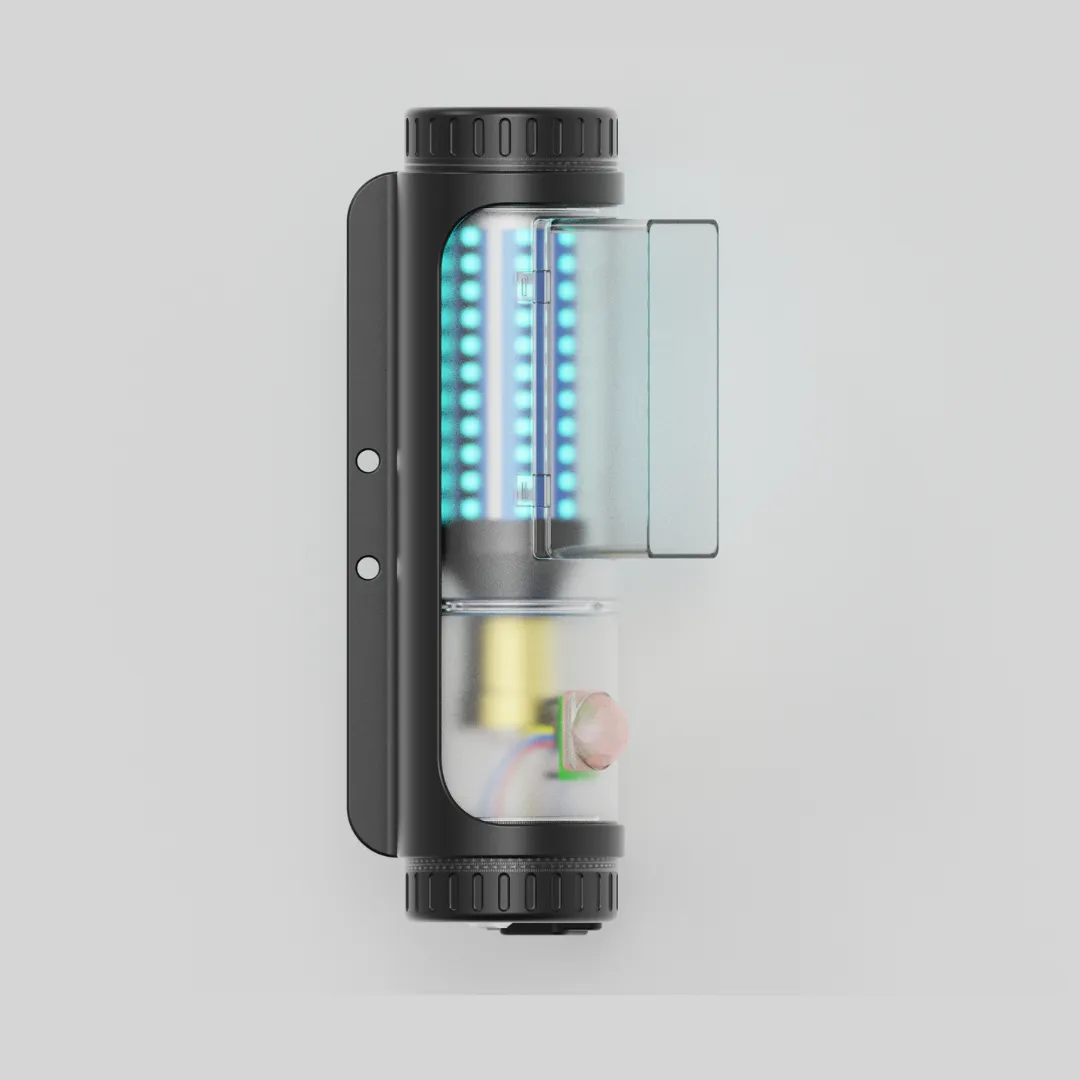

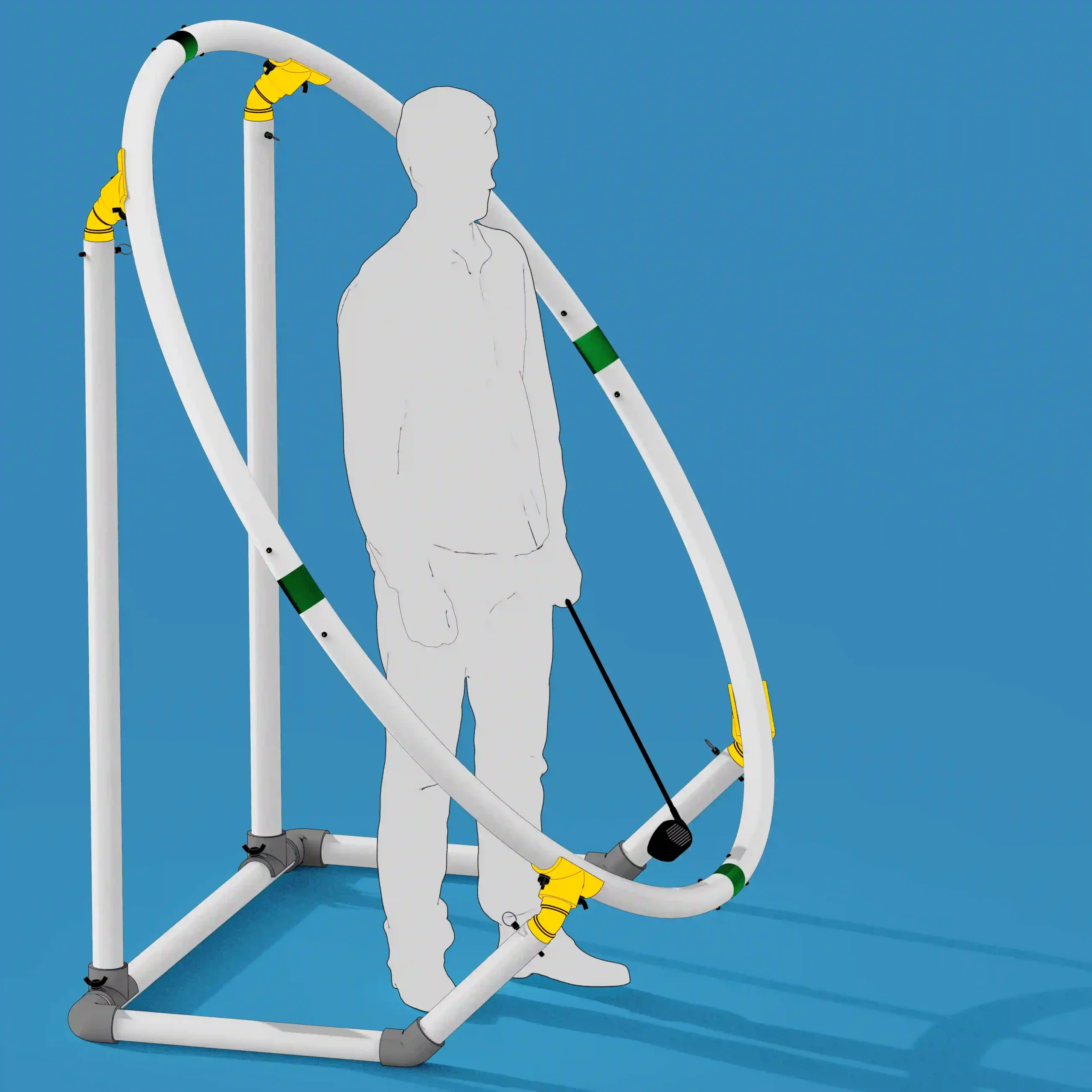

We take promising concepts and evolve them into robust, engineered solutions. Our industrial designers and mechanical engineers collaborate to iterate, prototype, and test every detail. From CAD development to full CMF (colour, material, finish) refinement and physical rig testing — nothing is left to chance.

05. Deliver

When your product is ready for launch, we make sure it's ready for real-world production. We work with trusted Australian and global manufacturers to bring your product to life at scale — managing everything from tooling and compliance to visual assets for investors, trade shows, and product launch campaigns.

Support

Our partnership doesn't end at delivery. We continue to provide post-launch support, technical guidance, and iteration assistance based on market feedback. Whether it’s scaling production, updating designs, or assisting with marketing materials — we’re here to back your success long-term.

Portfolio

Take a look at our portfolio to see how we’ve helped businesses across various industries transform their digital presence. Each project is a testament to our commitment to creativity, quality, and innovation.

FAQ

Frequently Asked Questions

Stay up-to-date with the latest trends in design, technology, and digital media. Our news section features insights,

updates, and stories from our team, showcasing our ongoing projects and industry innovations.

Our pricing is transparent and structured. We provide detailed estimates before initiating each project stage, with costs outlined for your clarity. A 50% deposit is required to commence work, with the balance due upon stage completion. We eschew hourly fees, focusing instead on delivering value.